Atlas F1 Technical Writer

The BAR-Honda team unveiled their challenger for the 2005 season with just one goal in mind: scoring their first Grand Prix victory. Having being very close in 2004, this year there will be no excuses. Atlas F1's Craig Scarborough analyses the changes and features on the new 007

Last year BAR launched the 006, which was an outwardly conservative car. Around the same time the interim 2002/2003 concept car was leading the times in testing; the subsequent pace of the 006 in testing and the opening races showed the new car allied to Michelin tyres was living up to its promise. Early season problems were largely down to engine failures caused by an imbalance in the oil system, causing oil starvation to either the top or bottom of the engine; these failures were almost all on Takuma Sato's car, and it is Honda's opinion that this was bad luck rather than any difference in engine spec or driving style.

Their use of Michelin tyres also harmed their race performances, which saw a lack of grip, a detail development ironed out the problems by the seasons end. Matched to their visually simple car were a number of technical innovations, such as the carbon gearbox and Alcon supplied brakes.

There was also an aggressive development strategy which adopted Renault's lateral thinking style to solutions. First of these was a three element rear wing with 20 slats to bypass the two element rule introduced for 2004; this was not deemed legal by the FIA. Then came a flexible rear wing flap, eventually protested and removed after on-car footage belied its existence. Finally came the torque biasing FCP (Front Clutch Pack) system linking the front wheels; this was initially protested and upheld on appeal, but the revised mechanical system was raced with some success from Monza onwards. The eventual second place in the Constructor's Championship was well deserved based on their consistency over the full season in comparison to their other rivals.

With this in mind they started the initial work on the new car. "We carried out analysis early last season in how we make the step to Ferrari," Willis stated, " and clearly we needed to make a challenging step forward", which resulted in the plan to have a brand new engine and brand new chassis. Yet the detail of the plan was interrupted: "we started with some very new aero concepts; we were part way into that design when the regulations changed. It all started to snowball, and we started to see better benefits".

With the development of this year's car originally halted by the new rules, some of the new directions the team wanted to take were shelved, although some of the planned developments were unaffected by the regulations and have appeared on the 007. With a new chassis and engine, Willis told me how much was carried over from the 006: "very few parts; there are only a handful of parts that are exactly the same", later explained to be parts like the steering wheel and pedals. The result was "the whole car is much more tightly packaged."

The car is still being developed in the open jet windtunnel at the back of the factory; the team have worked hard to operate this to the limits of its capabilities and transpose those results accurately to the track. They now have a project underway to create a new state of the art windtunnel to allow them to grow. Allied to this is the CFD team, which also forms a separate division for customer projects, allowing the team to bring in extra resources when needed from the external group. This methodical approach implemented by Willis works across all areas of the design and production departments, allowing otherwise complex projects to be delivered with few problems. The carbon gearbox was a clear example of this, when many other teams have struggled to make one sufficiently reliable.

Aerodynamics

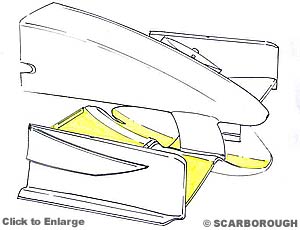

Following on from the principle adopted in 2001 when the front wing was first raised, the centre section of the wing curves to meet the lower allowable height. As it is lower the wing is working in ground effect, which is more effective than a conventional wing, increasing its potential to create downforce.

Geoff Willis had previously explained the potential problems of the lower middle section: "you have to be careful; you can't load the middle part of the wing too much without lowering the overall downforce of the car." The problem of the flow going under the car is not so critical: "not a lot of the flow goes under the shadow plate. There aren't a lot of complex flow structures coming off the middle part of the wing; it's the outer part of the wing that has most of the complex flow structures because there's a tip vortex coming off it."

But it's the flow that parts around the car that is the more critical area: "if you've got too big a flap section in the mid span, or you had too big a gurney on the mid span flap, you can sometime find that affects cooling". BAR have used a very long chord for the middle span of the wing, but have contoured the profile to be much less cambered, making the wing less aggressive and providing a cleaner wake; this wake gets picked up by the new bargeboards and sidepods fronts as explained later.

BAR's detail design work shows the transition to have a very flat profile; the main plane even being flicked up slightly at this point to make the cross section flatter. Once again the differing flows between the middle and outer section of the wing are effectively split by the new bargeboards.

Another feature of the front wing is the relationship of the wing to the endplates; as the wing has such a deep profile the main plane is only just above the endplate, while the highest part of the flap is meeting the top of the endplate. This loses some of the sealing effect of the endplate, but maximises the angle the wing can be run at. The endplates themselves are not as swept inward as those on last year's car, and the concave section on the lower trailing edge is less marked, as the endplate is now so much nearer the front wheel.

With such a large front wing the management of the flow trailing from it creates problems, for instance the brake ducts are now pointed downwards and pick up their cooling from under the front wing, a slightly less effective position than last year. The front of the monocoque has a larger clearance underneath, now heading all the way back to the sidepods with a clean sweep. Only the single keel mounting the lower wishbone obstructs this area.

As the flow tumbles back to the sidepods their front edges are gently undercut to ease the flow's path to beneath the flip ups. The sidepods are packaged with subtly angled and shaped radiators to allow the new front end shape. Thoughtfully, the team have split the bodywork from the sidepod fronts in a novel way, by creating the split around the circle of the lucky strike logo, leaving the logo fully visible on the detached bodywork to impress their sponsors. Beyond the leading edge the sidepods are largely following last years cooling format, with the exhausts moved inwards to narrow the coke bottle area.

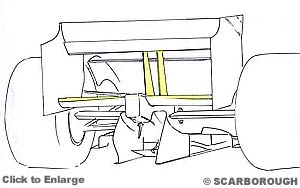

The floor ahead of the wheels and the diffuser layout are strangely devoid of fences and shaping, which may appear in a revised form before Melbourne. Perhaps a trend for 2005 is the rear wing now being mounted on central struts as seen on the new Toyota, albeit with BAR preferring two thinner struts over Toyotas single thicker one. The lower beam is now narrowed at its middle span, but wears a large gurney strip running all the way across the span of the wing.

Mechanics

Another notable partner is the NTN Corporation, who specialise in CV joints and angular contact bearings; as with their partnership with Alcon, BAR through Honda are finding new suppliers to find advantages.

Mechanics

In preparing the new engine, Kiuchi told us about the aims for the engine under the new rules: "it was our hardest challenge that we try to remain at top power. Normally in this position the engine designer prefers to select a safer way, which is to add some extra weight or reduce engine performance, but our position is to challenge that; we selected another way which is to take more advantage and maintain top power. Fortunately we also have a lighter engine and maintain top power", with the engine coming out as "more compact, with a lower centre of gravity to improve chassis performance."

The team have admitted some initial power loss will have occurred; this may be rectified by Melbourne from the results of the pre-season tests.

Coming out of a season where the team finally stepped up to take podiums and second position in the Constructors' Championship, their new car was eagerly awaited to see if it is capable of making it up the next step of the podium.

Now with additional financial support from Honda's buy in, as well as their supply of engines and chassis projects, the team have the resources to match their rivals. The consequence of this input, and the teams own technical direction, is a car that is the first to be truly optimised to the new rules. Only the release of their rivals' cars will see if BAR have met the challenge of a second season towards the front of the grid.

Now with additional financial support from Honda's buy in, as well as their supply of engines and chassis projects, the team have the resources to match their rivals. The consequence of this input, and the teams own technical direction, is a car that is the first to be truly optimised to the new rules. Only the release of their rivals' cars will see if BAR have met the challenge of a second season towards the front of the grid.

Geoff Willis summarised last year as "a very good year - we were able to keep our car developed to keep pace with Ferrari", but he was aware there was still a performance gap to Ferrari which needed to be identified. "Last year's car didn't have any individual problem at all, it just needed to be better in every area; aero, weight reduction, centre of gravity, and power characteristics. It's those areas we will develop."

Geoff Willis summarised last year as "a very good year - we were able to keep our car developed to keep pace with Ferrari", but he was aware there was still a performance gap to Ferrari which needed to be identified. "Last year's car didn't have any individual problem at all, it just needed to be better in every area; aero, weight reduction, centre of gravity, and power characteristics. It's those areas we will develop."

Catching most of the attention at the launch was the heavily curved front wing. The entire front end is more optimised to the new rules than any other new car seen so far. While Willis suggests this is a front wing format that will be adopted by many other teams, BAR have got the design out and testing long before their rivals. At the press conference he noted this about the changes at the front: "the problem is getting front downforce without damaging the flow underneath the rest of the car. This is the start of our solution. I am sure it is an area with a big rule change. The front wing will see a lot of development through the year, and I think we will be interested to see where other people's solutions are." In essence the whole front end is an aggressive approach to clawing back as much downforce as they can from the raised front wing, while trying to retain as cleaner flow to the rear as possible.

Catching most of the attention at the launch was the heavily curved front wing. The entire front end is more optimised to the new rules than any other new car seen so far. While Willis suggests this is a front wing format that will be adopted by many other teams, BAR have got the design out and testing long before their rivals. At the press conference he noted this about the changes at the front: "the problem is getting front downforce without damaging the flow underneath the rest of the car. This is the start of our solution. I am sure it is an area with a big rule change. The front wing will see a lot of development through the year, and I think we will be interested to see where other people's solutions are." In essence the whole front end is an aggressive approach to clawing back as much downforce as they can from the raised front wing, while trying to retain as cleaner flow to the rear as possible.

The other issue with wings of vastly different shapes across their span is the point where the profile twists to meet the higher and lower sections. BAR's aerodynamicist Willem Toet enlightened me on the problems in this area: "they're big structural bits, so you've got drag and you've taken all the energy out of the air. It's not working for you, because it's working sideways, so it's not giving you downforce." He added that a move towards a smoother transition will evolve over time as the wing design develops.

The other issue with wings of vastly different shapes across their span is the point where the profile twists to meet the higher and lower sections. BAR's aerodynamicist Willem Toet enlightened me on the problems in this area: "they're big structural bits, so you've got drag and you've taken all the energy out of the air. It's not working for you, because it's working sideways, so it's not giving you downforce." He added that a move towards a smoother transition will evolve over time as the wing design develops.

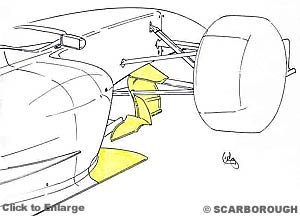

Picking up and shaping all this flow are the bargeboards. These are fundamentally the same format as last year, with a fin at the top (termed a tool tray by BAR staff) and a small turning vane, leading back to the wide fins in front of the sidepods. This year the tool trays and vanes are carried over, with the vane now being much more curved and mounted closer to the car's centreline in order to split the flow off the front wing. An extra vane has also been added to turn the flow acutely outwards. To stop this flow heading under the floor there is a section of floor trailing from the vane (termed a hammer head by BAR). The sidepod fins have now adopted a Williams design from late last year where they sprout from the outer edge of the sidepod, with the missing inner section is partly replaced by a V shaped fin near the shadow plate.

Picking up and shaping all this flow are the bargeboards. These are fundamentally the same format as last year, with a fin at the top (termed a tool tray by BAR staff) and a small turning vane, leading back to the wide fins in front of the sidepods. This year the tool trays and vanes are carried over, with the vane now being much more curved and mounted closer to the car's centreline in order to split the flow off the front wing. An extra vane has also been added to turn the flow acutely outwards. To stop this flow heading under the floor there is a section of floor trailing from the vane (termed a hammer head by BAR). The sidepod fins have now adopted a Williams design from late last year where they sprout from the outer edge of the sidepod, with the missing inner section is partly replaced by a V shaped fin near the shadow plate.

Mechanically the car has been revised only in detail; the dampers supplied from Showa are still telescopic types at the front, and the wishbone geometry follows last year's BAR practice and not Williams drooped upper wishbone format. At the rear the gearbox is a development of the 2004 carbon fibre case with Honda internals; work has been completed to make it lighter and easier to manufacture as Willis noted: "we have been working together with Honda on the internals development, and we are constantly working at ways of improving; shift performance, lighter weight and lower loss on gearbox internals. Also the carbon main case we launched last year is now a second generation version; it is significantly lighter again, but also just as important considerably easier to manufacture. As we launch the car now we have 7 or 8 gearboxes available to test, so that's a big improvement both technically and in terms of operation."

Mechanically the car has been revised only in detail; the dampers supplied from Showa are still telescopic types at the front, and the wishbone geometry follows last year's BAR practice and not Williams drooped upper wishbone format. At the rear the gearbox is a development of the 2004 carbon fibre case with Honda internals; work has been completed to make it lighter and easier to manufacture as Willis noted: "we have been working together with Honda on the internals development, and we are constantly working at ways of improving; shift performance, lighter weight and lower loss on gearbox internals. Also the carbon main case we launched last year is now a second generation version; it is significantly lighter again, but also just as important considerably easier to manufacture. As we launch the car now we have 7 or 8 gearboxes available to test, so that's a big improvement both technically and in terms of operation."

After suffering innumerable failures in the first year of the new engine reliability rules, the two weekends per engine rule should worry Honda. Yet they were boasting incredible power outputs for last year, and feel the spate of unreliability was down to two specific issues with the valve train and in the oil system. In their preparation for 2005 they have focussed less on outright power output and focussed on reliability and drivability. The latter comment from Takeo Kiuchi was telling, as most accept the Honda as one of the most powerful engines; its drivability was often cited as a weakness, Kiuchi stating he was "disappointed at the situation where our driver takes a few laps to overtake our competitor."

After suffering innumerable failures in the first year of the new engine reliability rules, the two weekends per engine rule should worry Honda. Yet they were boasting incredible power outputs for last year, and feel the spate of unreliability was down to two specific issues with the valve train and in the oil system. In their preparation for 2005 they have focussed less on outright power output and focussed on reliability and drivability. The latter comment from Takeo Kiuchi was telling, as most accept the Honda as one of the most powerful engines; its drivability was often cited as a weakness, Kiuchi stating he was "disappointed at the situation where our driver takes a few laps to overtake our competitor."

|

Contact the Author Contact the Editor |

Please Contact Us for permission to republish this or any other material from Atlas F1.

|

Volume 11, Issue 3

Articles

Interview with Nick Fry

Technical Analysis: BAR 007

Technical Analysis: Sauber C24

Regular Columns

On the Road

Elsewhere in Racing

The Weekly Grapevine

> Homepage |